Climatism is the exclusive representative of Blygold in Greece, and thus able to offer Blygold’s products to protect any HVAC equipment against corrosion. The Blygold protection system has been applied globally to major projects in various sectors — from hotels, hospitals and museums to factories and airports!

Long lasting HVAC condenser coil coating

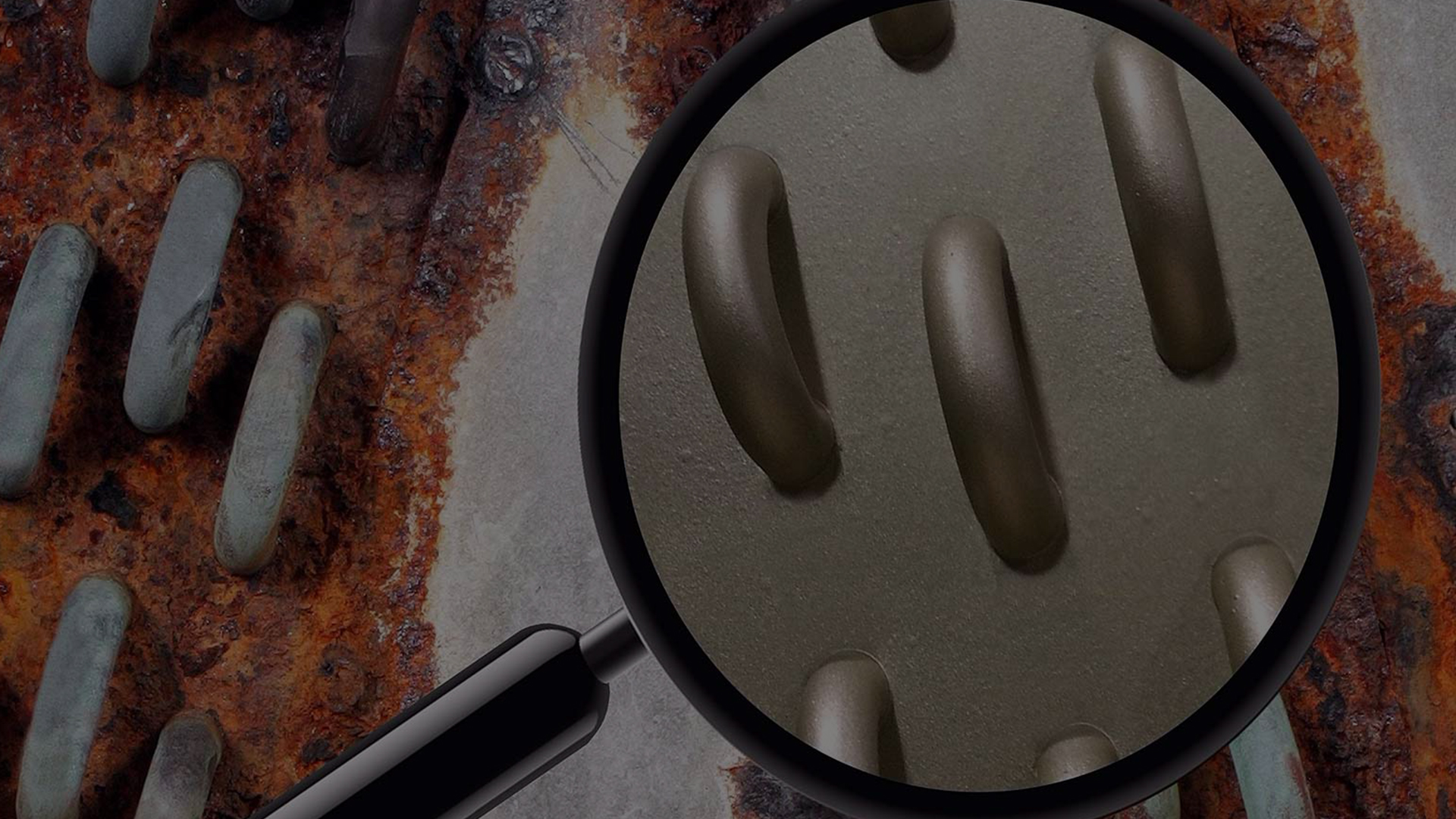

Air conditioners operating in a “harsh” environment —such as those near the sea— need special protection, as corrosion dramatically affects their performance. Corrosion occurs due to toxic rain, sea salt particles as well as other exogenous factors.

Air-cooled heat exchangers are very sensitive to corrosion, which unfortunately significantly affects their performance. An eroded air-cooled heat exchanger causes higher condensing temperatures, resulting in higher consumption.

Oxidation

When dissimilar metals are electrically connected in the presence of an electrolyte, then we have a reaction. This reaction is known as galvanic corrosion or electrolysis. Galvanic corrosion often causes damage to the fins, especially at the points where they are joined to the pipes, which can eventually lead to the destruction of the heat exchanger.

Other forms of oxidation are caused by chemical reactions to the environment. Unprotected metals in an industrial environment will eventually lead to a drastic reduction in the cooling capacity of the unit. Sulfur and Nitrogen often cause the corrosive process to start.

Microbial growth

Companies use air-cooled units to control temperature and improve hygiene conditions. In practice, however, the exact opposite may be the case. Because of the combination of humidity, continuous flow of pollutants (from the air intake) and a specific temperature, refrigeration units can become permanent sources of infection, with the growth of microbes.

In addition to the risk of an unhealthy environment, micro-organisms also affect metals and therefore reduce the life and performance of the units. Microbiological air measurements will inform you about the hygienic conditions of refrigeration units.

Reduced efficiency

Contamination and oxidation have a tremendous impact on the efficiency of refrigeration units. Oxidation will affect heat transfer between copper tubes and aluminum fins. The presence of pollutants will reduce air flow in the heat exchanger. The condensation temperature of the system will rise and the system will require more energy, while cooling capacity will be reduced.

This means that, when you need air conditioning the most, the system may let you down. Detailed inspections and measures to reduce energy consumption must be implemented and there also must be continuous monitoring of the heat exchanger.

BLYGOLD IS THE SOLUTION

It is a revolutionary method, designed to prevent the corrosion of HVAC condenser coils.

PROTECTION OF HEAT EXCHANGETS BLYGOLD

The Blygold protection method is revolutionary, designed to prevent corrosion and hence loss of heat exchanger capacity. This method consists of chemical cleaning, the primary chemical coating and the application of the final coating. The type of final coating depends on the surrounding area of the heat exchanger.

The Blygold protection method can be applied inside the factory or in the installation area. Both new and corroded heat exchangers can be protected to prevent or stop further erosion.

Blygold’s products and services are used around the world in many unique situations. The Blygold protection system has been applied globally to major projects in various sectors — from hotels, hospitals and museums to factories and airports. Although applications are often very different, they all have a common element: when it comes to the maintenance, operation and operation of heating, ventilation and air-conditioning equipment, the owners of the units give priority to a healthy, low power consumption environment.

Blygold Process

1st Stage

- INSPECTION & CLEANING: The element to be processed is examined thoroughly. Impurities are removed with an absorption device. The element is then cleaned with water and biodegradable materials.

- FIN ALIGNMENT: With the help of a special accessory (comb), the fin inclination angle is carefully and meticulously adjusted.

- DEOXIDATION: If corrosion is already present, the oxides are removed with a special method of purification (dilute acid solution) and then rinsed with plenty of water.

2nd Stage

- PRIMARY COATING: This coating is applied with full coverage techniques that improve adhesion and provide basic protection.

- DRYING: The final coating can only be applied when the element is completely dry.

- 3. FINAL COATING: The final coating is always applied in accordance with the specifications of Blygold International B.V., in order to achieve maximum efficiency.